![]()

We apply a system-level approach to designing a microorganism and production process at the same time. This lets us reshape every part of a cell’s complex internal machinery for maximum efficiency. We call this bioengineering.

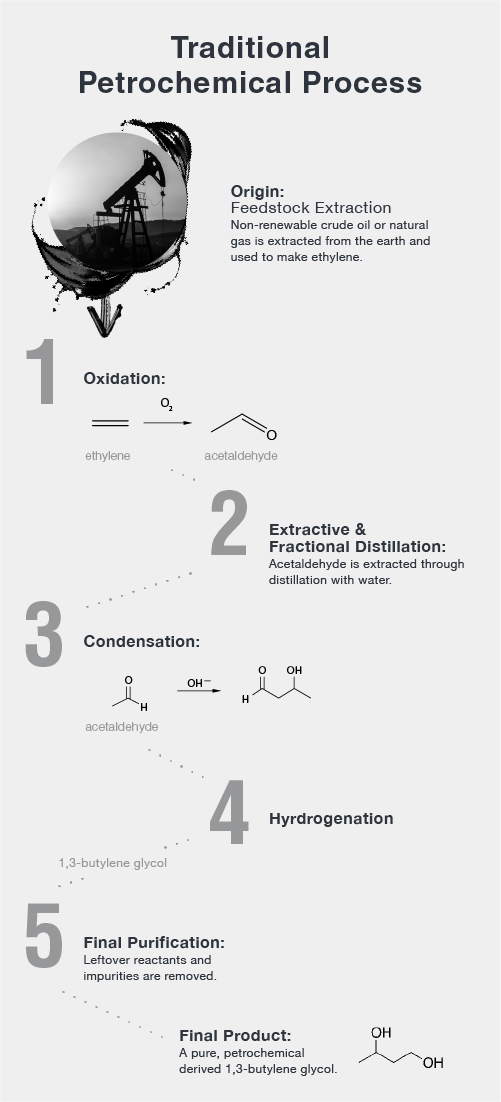

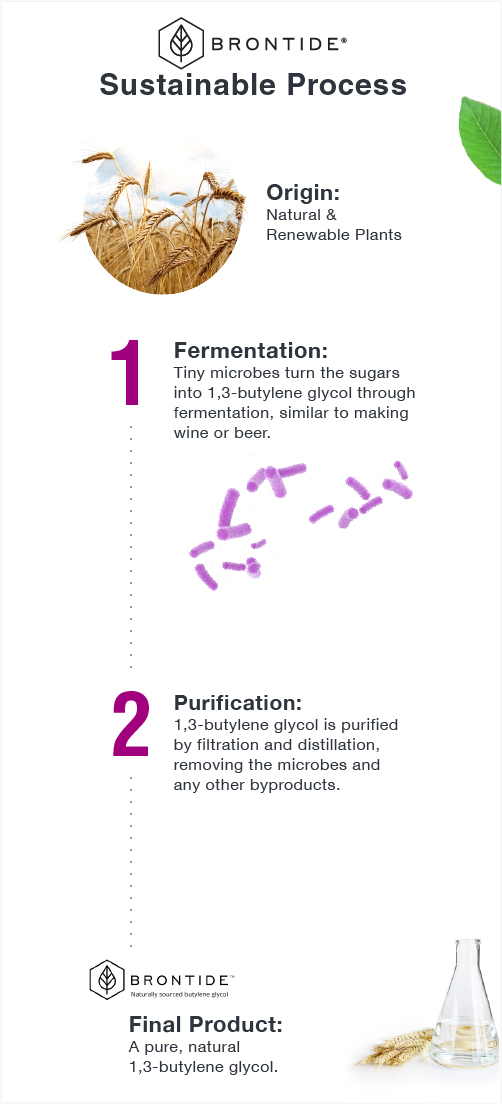

For thousands of years, fermentation has been used to create staples of our society.

We have fine-tuned this ancient technology by introducing a catalyst, a proprietary microbe that under precise temperatures and conditions efficiently ferments sugar extracted from plants into 1,3-butylene glycol in a direct one step process.

Winner of the EPA 2020 Green Chemistry Challenge Award, Brontide® natural butylene glycol is sustainably produced and can help lower your product’s environmental impact.

our biobased processes can help the personal care industry meet the consumer demand for natural and sustainable products without compromising on performance